We're looking for the right CNC Machinist

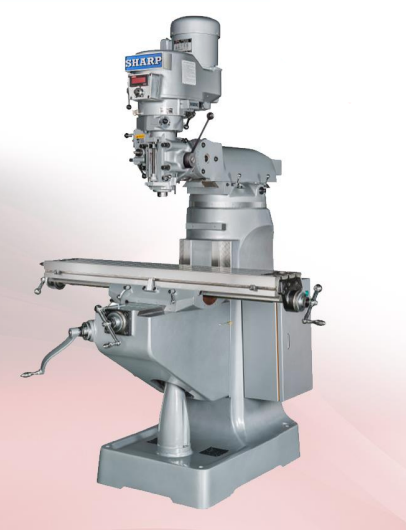

S&S Machining is growing fabrication shop and valued employer in central Texas. We offer CNC/Manual prototyping and production machining for turnkey and JIT fabrication for our customers nationwide. S&S Machining is looking for CNC Machinists to add to this quality-focued and customer-oriented team.

About S&S Machining